Worse, you will burn bridges, reinforce the dissonance and, eventually, you’ll get removed from the table. If you try to address everything at the same time, you’ll fail. Once you get into the operational side of things, you’ll be overwhelmed by how much there is to learn, and by the amount of technology and processes you’ll need to protect. The other key mindset for IT is patience.

#Industry 4.0 elements how to

You have to make sure you figure out how to maintain it before you can figure out how to protect it. That means spending time on the factory floor talking to factory staff and management to get deep in the weeds to understand the methodology they are using for quality, efficiency, and everything in between. It’s a different world, and if IT doesn’t understand that world–if we don’t take the time to live in that world–then how can we possibly go about protecting it? We can’t go in talking about the factory floor in the same language and terms that we would talk about a traditional office environment. So there is a minimum “pay to play” mindset of operational excellence that has to be put in place to even get a seat at the table.Īt the table, the IT team must be prepared. Firstly, if we can’t keep the printers and computers on the factory floor running, there’s no way we’re going to be invited in to even talk about securing the environment. Let’s look at some ways IT can do our part.Į arn our seat at the table. How IT Can Support the Changes Needed for Industry 4.0 So both sides will need to drop tradition and ego to create a win-win situation for the organization. If the IT team is somehow iced out, the factory may run just fine, but business operations are substantially more vulnerable to a major disruption due to a cybersecurity attack. This means they’ll need to be able to bend a little to let IT be part of their conversations. IT needs to figure out how to reduce its need to control everything, so that teams can protect what needs to be protected while supporting the operational technology (OT) environment in ways that don’t negatively impact productivity, efficiency, and automation on the factory floor.Īt the same time, the factory needs to understand that they are not technologists and don’t have a wide enough scope to view the entire environment in order to protect OT.

What’s needed now is a growing understanding on both sides, so the divisions and dissonance are eliminated, and cooperation and teamwork are celebrated.

Whether that’s the security of the entire organization, or the efficiency and efficacy of the operational technology on the factory floor, neither scenario is acceptable as they’re both preventable. But, in many organizations, the traditional dissonance between IT and the factory floor is still there leading to conflicts in which the health and security of the business are jeopardized due to misalignment. Today, it’s almost mandatory that IT sits in the middle of the factory and is seen as a valuable partner and an essential business function. In the world of Industry 4.0, the separation between IT and the factory floor pretty much disappears.

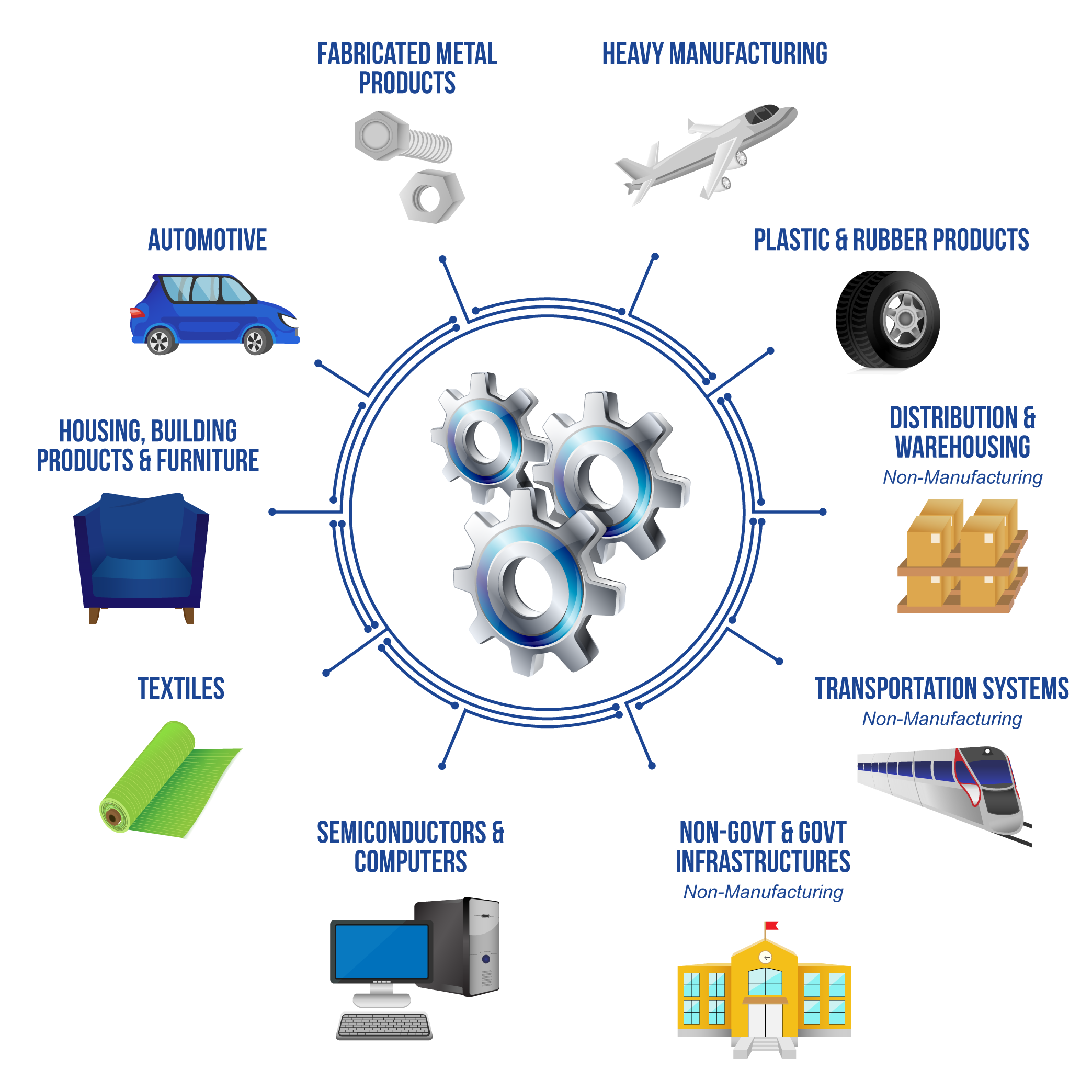

Industry 4.0 Requires New Ways of Working Together And in the past, that was really the best approach, because the controls that IT needs-particularly for security-typically aren’t conducive to maintaining an efficient and optimized factory environment. Traditionally, the value of IT in the manufacturing industry has been to provide the factory floor with the resources they need, and then to stay out of the way. Where I see the biggest dissonance today is in how companies are allowing both IT and the manufacturing groups to exist inside their organizations. While the possibilities of Industry 4.0 are extraordinary-and realizing them is seemingly just within our reach-there are still obstacles to overcome before we can feel truly comfortable making them a reality. Manufacturing can be faster, more data-driven, more responsive to the needs of workers and customers, and more powered by innovations such as artificial intelligence, internet of things, digital supply chains, and blockchain. Industry 4.0 has vast potential to transform what factories can do.

0 kommentar(er)

0 kommentar(er)